The industrial landscape of South Asia is entering a phase that few decades ago would have seemed futuristic. Automation, robotics, and artificial intelligence are no longer confined to isolated factories or advanced economies; they are rapidly becoming integral to manufacturing, logistics, and service operations across the region. Yet, the real transformation is not simply replacing human labor with machines. It is the intelligent collaboration between humans and automated systems that is redefining productivity, innovation, and competitiveness.

Automation has long been associated with efficiency, faster production, lower error rates, and reduced costs. In South Asia, industries such as textiles, electronics, and pharmaceuticals are adopting robotic process automation to streamline repetitive tasks, improve quality control, and enhance throughput. Advanced robotics in warehouses and manufacturing plants are now performing tasks ranging from sorting and packaging to precision assembly. These changes allow companies to achieve scale without proportionally increasing labor costs, a critical factor for economies striving to remain competitive in global markets.

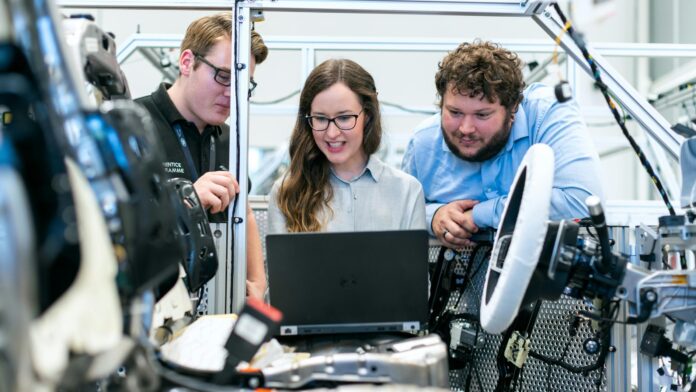

However, the most strategic gains emerge from human-machine collaboration. Rather than replacing workers, automation is enabling them to focus on higher-value functions, problem-solving, innovation, and customer engagement. In logistics hubs, for example, autonomous vehicles and automated cranes handle the movement of containers, while human supervisors oversee operations, analyze real-time data, and make decisions that machines cannot. This synergy improves operational accuracy, reduces downtime, and accelerates responsiveness to changing market conditions.

Predictive analytics and machine learning further enhance this collaboration. Systems can forecast equipment maintenance, optimize supply chains, and monitor workflow efficiency, providing humans with actionable insights rather than raw data. In manufacturing, AI-powered monitoring allows engineers to identify inefficiencies or potential breakdowns before they occur. Workers can then intervene strategically, combining machine precision with human judgment, a combination that outperforms either alone.

For South Asian economies, this convergence presents a strategic opportunity to elevate industrial competitiveness. Countries like India and Singapore have invested heavily in smart factories and automated logistics networks, setting benchmarks for efficiency, safety, and sustainability. Sri Lanka and Bangladesh, with rapidly growing export sectors, can leverage automation not only to scale production but also to improve reliability, traceability, and quality, factors increasingly demanded by international clients. In sectors like apparel, electronics, and agribusiness, integrating automated systems with human oversight can reduce defects, improve compliance, and strengthen brand value in global markets.

The transition is not without challenges. Workforce adaptation is critical. Many employees must acquire digital literacy, data interpretation skills, and technical expertise to work effectively alongside automated systems. Governments and corporations are beginning to address this through reskilling programs, vocational training, and industry-academia partnerships. Strategic policy support, such as tax incentives for automation investments or grants for workforce development, will determine the speed and scale of adoption.

Sustainability is another strategic dimension. Automation and AI reduce waste, optimize energy use, and lower carbon footprints, aligning industrial growth with environmental objectives. Automated monitoring can track resource consumption in real time, enabling industries to operate efficiently while adhering to global ESG standards. For South Asia, where industrialization is accelerating alongside climate concerns, integrating sustainability into automation strategies is not optional, it is essential for global competitiveness and long-term resilience.

Ultimately, the industrial future of South Asia will be defined by the ability to harmonize human ingenuity with machine precision. Automation provides the tools, but humans provide judgment, creativity, and strategic foresight. Organizations that master this collaboration will achieve higher productivity, improved quality, and enhanced adaptability in a volatile global market. Those that view automation solely as a cost-cutting measure risk missing the broader opportunity of intelligence-driven growth.

In the next industrial era, success will belong to the economies and companies that embrace not just machines, but intelligent collaboration, a model where technology amplifies human potential rather than replaces it. For South Asia, this approach offers the chance to leapfrog into a new era of industrial sophistication, competitiveness, and sustainable growth, ensuring that the region not only participates in the global economy but thrives within it.